|

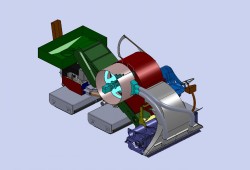

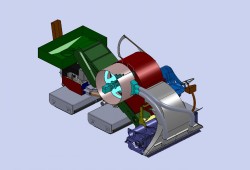

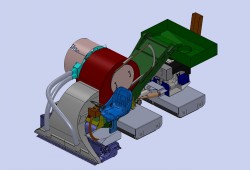

Design Objective:

To dry harvest cranberries without sacrificing quality and freshness so that producers can offer a high quality fruit with an extended shelf life.

Solution:

A vacuum harvester with an adjustable picking head. These units are hydraulically powered and come with a 6 foot picking head width. Harvester can be mounted on a mobile bridge, or self-propelled

|

|

Performance Specifications:

This new wider harvester was designed for mounting onto a self-propelled bridge which operates on tram lines. The harvester side shifts after every consecutive pass and can rotate 180 degrees.

The bridge engine powers the vacuum rotor, oscillating tine head, and extraction conveyor. Extracted fruit is conveyed off the bridge into bulk bins that are set down along the tram line.

Three hydraulic motors and two cylinders run on this machine. Power requirements for these is as follows:

- Vacuum Rotor: 40 HP max @ 4000 rpm

- Harvest Head: 10 HP max @ 200 rpm

- Discharge Conveyor: 3 HP max @ 30 rpm

- Harvester Head Tilt Cylinder: max 2500 psi

- Oscillating Tines Depth Cylinder: max 2500 psi

Cross runner pruners are built into each tine, these are set on one-inch centers. The pruners work in conjunction with the forward/reverse oscillation of the tines. This oscillation motion untangles (combs) the runners as the machine moves forward. To prevent uprooting, an adjustable pressure roller behind the tines forces the vine down, preventing it from rising up and plugging the tines.

Fruit is stripped from the stems as they pass through the 1/4 inch gap between the tines. The detached fruit is immediately sucked into the vacuum chute above, dropped onto the discharge conveyor in the vacuum chamber, and then conveyed out. |

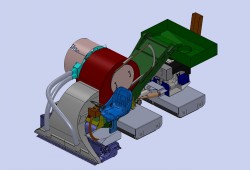

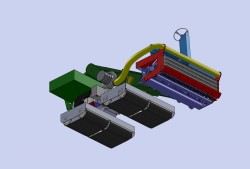

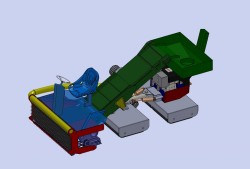

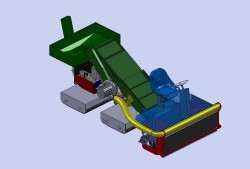

New Design - 2011: Self Propelled Vacuum Harvester

|

Design Objective:

To design a powertrain to convert the bridge mounted harvester to a self propelled unit.

Solution:

A center steer chassis with dual pad trac drive system.

|

|

Features:

- 180 degree discharge hopper - 300lb capacity.

- Pad track drive - minimum ground pressure and slippage.

- Diesel/hydraulic powered.

- 66" Harvester Head

|

|

Overall Dimensions:

- Length - 144"

- Width - 68"

- Height - 60"

- Weight - 2700 Lbs

|

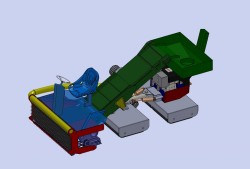

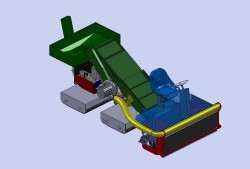

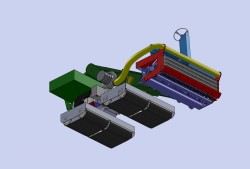

New Design - 2011: Self Propelled Reel Pick-Up Harvester

|

Design Objective:

To reduce the power requirements of the harvester without sacrificing capacity or fruit quality.

Solution:

Replace the vacuum pickup system with a vertical reel pickup.

|

|

Features:

- 180 degree discharge hopper - 300lb capacity.

- Pad track drive - minimum ground pressure and slippage.

- Diesel/hydraulic powered.

- 66" Harvester Head

|

|

Overall Dimensions:

- Length - 144"

- Width - 76"

- Height - 60"

- Weight - 2100 Lbs

| |